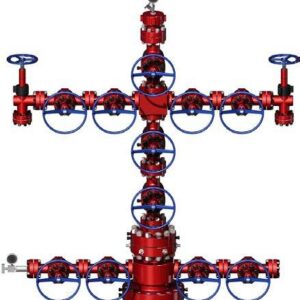

Description

The GPZ ram BOP is available in EU, U and ES models. It is designed and manufactured in accordance to API 16A requirements and is available in a variety of sizes and specifications

■ Working pressure: 2000 psi ~ 20000 psi

■ Nominal diameter: 71/16″ ~30″

■ Working media: oil, gas, mud, including H2S and CO2 gases

■ Temp Class: T75, T20,T0

■ Metal seal temperature level: A ~ D (-15oF/-26oC ~ 250oF/121oC)

■ Rated hydraulic controlled working pressure: 3000 psi

■ Recommended working pressure: 1200 psi ~ 1500 psi

■ Upper and lower connection: the upper flange, planted wire, clamp connection; the lower flange, planted, clamp wire connection

■ Lock: hydraulic and manual lock

■ Fluid containment specifications: 1″NPT

■ Optional ram: half sealing gate, sealing ram, shear ram

■ Outlet side connection: flange, silk, clamp connection