Description

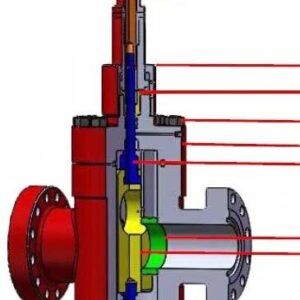

Tungsten-Carbide Wear Brushing

The overlay applied to the face of the wear brushing increases the service life and improves the extensibility of wear brushing. This helps to accept abrasive downstream turbulence, especially during unbalanced drilling operations.

Multiple Applications

Both remote control and on-site manual operation are available during onshore and offshore operations.

Features:

■ Built for oil fields;

■ Precision manufacturing;

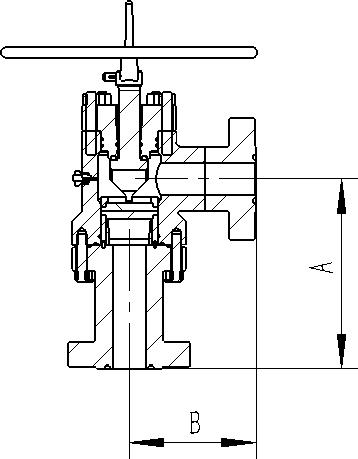

■ One-way plate to plate design;

■ Wear-resistance tungsten carbide wear bushing increases its service life;

■ Versatile for onshore and offshoreoperations;

■ On-site control or remote