Description

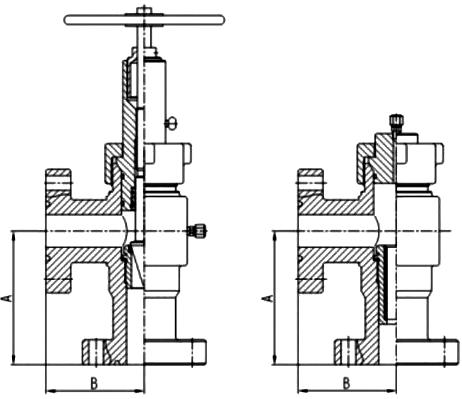

Specifications:

■ Working pressure: 2000 psi ~ 20000 psi

■ Working pressure: 21/16″ ~31/16″

■ Working media: oil, gas and various drilling fluids

■ Working temperature: LU (-51oF/-46oC ~ 250oF/121oC)

■ Material grades: AA, BB, CC, DD, EE, FF, HH

■ Specification level: PSL1 ~ 3G

■ Performance level: PR1 ~2

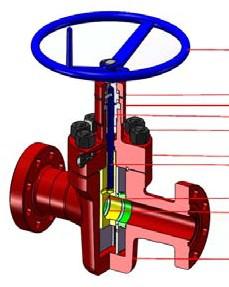

Positive Choke Valve

■ Choke bean material is fabricated from ceramic and tungsten carbide, which has sufficient corrosion resistance, anti-erosion and wearablecapacity;

■ The valve adopts a union bonnet so as to change choke quickly;

■ The valve can be applied to wellheads, christmas trees and choke lines.